Call us “sole makers”

We are a company active since the early seventies in the production of soles, born with the aim to grow in between one of the most famous Italian supply chain: the Tuscan Leather District.

Over the years and our entrepenuer history, starting from San Miniato, our business has opened to international markets, technological innovation and new materials, first of all the polymeric materials.

Artisan excellence and innovative spirit

Making quality wearable. We integrate the expertise of our craftsmen with the best processes and product technologies to always be a reference point in the world of fashion luxury and sportswear.

Dynamic nature

To grow pursuing sustainable innovation and ensuring environmental, social and local well-being.

We've come a long way

Vamas' story began in the early 1970s. It is the entrepreneurial, professional and human story of a group of artisans driven by an ambitious idea: to put to good use the skills acquired in leather processing and become a leading manufacturing company.

We have always had a positive attitude to problem-solving: we respond to our customer needs and requests with ideas that respect their deadlines, taste, and expected standards. When it comes to quality, we never compromise: "Quality over quantity."

And now that the company is led by new, younger, and even more creative minds, our desire to experiment and innovate is stronger than ever. We know that making the entire production process efficient means taking into account and implementing many different elements and factors. Each phase must be carried out respecting the highest performance criteria. The goal is always to optimise performance and achieve the quality levels our customers expect from us.

The future is here, just a few steps away.

We put passion into everything we do

Innovation

Being open to change is part of our corporate DNA. Innovating means continuing to grow.

Sustainability

We have always done our utmost to respect the planet and guarantee a brighter future for the next generations. We have always looked for better solutions to reduce the amount of waste we produce and recover the materials.

Respect

For what we do and what others do, but also for the human capital, our local area (which has given us so much) and our business partners.

Collaboration

We build relationships with our customers based on effective communication and trust, creating shared projects that fully satisfy all their needs.

Traceability

We want every stage of the process to be transparent, because the result is as important as the path to get there.

Passion

We like what we do and never cease to seek new methods, materials and applications.

Quality

We always strive to maintain our main focus on quality.

Networking and teamwork

Today Vamas counts five industrial plants, called Laboratories, where all the different production steps take place. Aside from our main base in San Miniato (Tuscany), we have partner companies in other areas of Tuscany, as well as in the Marche and Romagna regions.

Our main plant since 1997. This was and still is where all our new products are designed, as well as the home to our historic leather department and main offices.

This laboratory has been designed to respond to the growth of the sneakers market and it’s still the home of the TPU injection departments. From 2020 it also hosts the graphics department, which was created to satisfy all the customization requests.

Established in 2017, this laboratory was created to meet the general growth in demand.

Vamas’ continuous growth has made it necessary to further expand to maintain high production performances, so in 2019 we opened this new laboratory from the redevelopment of a dismissed tannery.

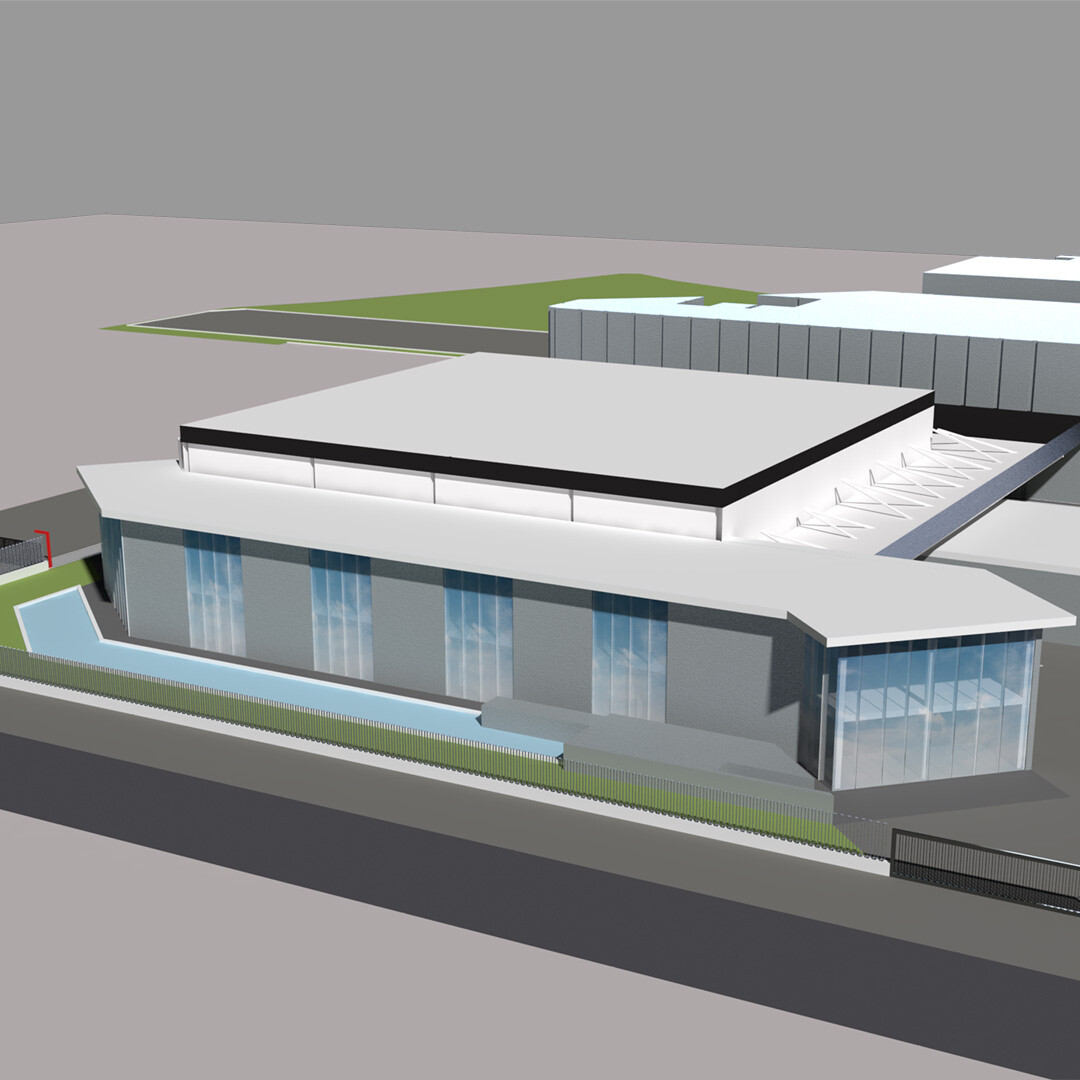

Starting over, again. After fifty years, we will open a new space: the Lab0, obtained through the adaptive reuse of an old company, which will be Vamas’ new logistic hub.

After many years of collaboration with several business partners, our supply chain agreement, signed in 2018, effectively formalised our relationship with local companies.

Our supply network is so extensive it involves 19 local companies, for a total of about 500 employees. Each year, together, we produce up to 5 million pairs of soles.

We love our area and we’re very grateful for it. Tuscany has gifted us its prestigious artisan know-how, so we want to reciprocate the favor by giving back more work and creating a virtuous circle that can make our local supply chain work.

Working side by side with the other companies in the supply chain means ensuring a greater and more widespread use of the best practices, aiming to share a common know-how and build a functional network.

To expand our technical know-how we have also partnered up with a polyurethane specialized laboratory, located in the Marche region footwear hub.

Figures

Sold record per year

Employees of the company

Variations designed in one year

Productive area over 5 Lab